For lead-acid battery, there need many different kinds of machines, such as grid casting machine, board pasting machine, etc.

I. Lead-acid Battery Grid Casting Machine

This product has been discontinued and removed from our shelves.

This machine is specially designed for casting board and grids used in batteries. It can melt lead, keep constant mould temperature, feed certain lead liquid, cast and trim edge, all in one machine.

Description

The lead-acid battery grid casting machine is specially developed for melting lead alloy powders. It can also be used for automatic casting and cut-to-length.

Technical Parameters of Lead-acid Battery Grid Casting Machine

| Item | Specifications | ||

| Applicable board size | 400mm×(100-165)mm | ||

| Suitable board thickness | 1.2-4.0mm | ||

| Applicable alloy for grid | Lead-Antimony | Antimony 1.6-4.5% | |

| Lead-Calcium | Calcium 0.08-0.14% | ||

| Production speed | 6-17pcs/min (large size) | ||

| Total power | 43kW | ||

| Actual power consumption | 26kW | ||

| Melting pot volume | 1.5 tons | ||

| Melting pot temperature range | 430-550℃ | ||

| Casting mould temperature range | Upper mould | 150-170℃ | |

| Lower mould | 179-190℃ | ||

| Lead feeding pipe temperature range | 450-520℃ | ||

| Lead ladle temperature range | 450-550℃ | ||

| Machine dimension | 3450×900×1800mm | ||

Note: There are several different kinds of grid casting machines for your selection. For example, this machine can be equipped with one pot and two casting machines for high production capacity. Machine for bigger grid size of 710×(140-250)×( (3-6)mm is also available from us.

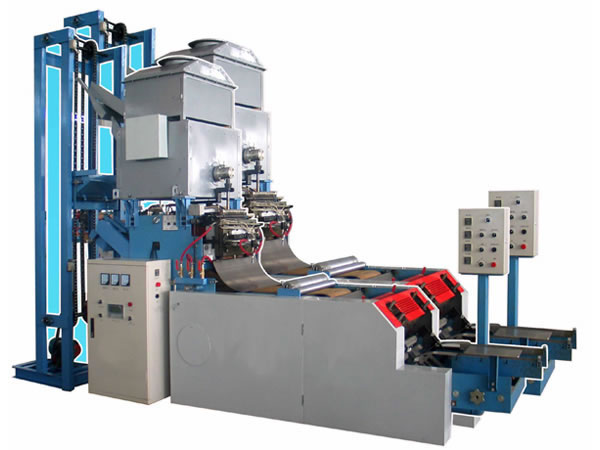

II. Lead-Acid Battery Grid Pasting Machine

Description

As the name implies, the lead-acid battery grid pasting machine is generally employed for coating diachylon to grids. Full automatic, the working process includes pasting, pressing and acid pouring.

This range of product can be classified into single-side grid pasting machine and double-side grid pasting machine. The double-side grid pasting machine can paste diachylon to both anode and cathode side.

Main Technical Data of Lead-Acid Battery Grid Pasting Machine

| Item | Specifications | |

| Applicable grid size | Length | 180-380mm |

| Width | 110-170mm | |

| Thickness | 1.0-4.5mm | |

| Capacity of diachylon hopper | About 150kg | |

| Production speed | 60-120pcs/min | |

| Pasting thickness error | ≤±0.1mm | |

| Pasting weight error | ≤±5g | |

| Total motor power | About 12.3kW | |

| Compressed air | 0.7MPa, 0.3m3/min | |

| Machine dimension | 3760×1700×1650mm | |

| Weight | About 2000kg | |

For the production of lead-acid battery, users also need other machines. Here is the list for the equipment required.

1. Vacuum diachylon mixing machine

2. Grid surface oven-drying device

3. Lead powder milling & oxidizing equipment

4. Lead-acid battery formation & test equipment

Battery Activator

The BA3930/3932 intelligent battery activator is a portable instrument for daily maintenance of single cell which has lag-out properties in one lead acid battery. It plays three roles for comprehensive solutions: charger (DC power supply), discharger (DC load bank) and activator.

These three functions can be used individually or comprehensively. When used comprehensively, lag-out battery will experience low-volt constant current charging and discharging singly or in multi-circles (1~99). By activating the disabled Active Material on battery electrode plate, it amends the cell malfunction caused by chemical failure and thus boosts the capacity of old cell. Activation curve and certain parameters (e.g.: voltage and resistance) will display on screen as activation ends.

Technical Parameters of the Battery Activator

| Parameters | Measurement Mode | Resolution | Accuracy |

| Charging current | 1-100A (2V) 1-30A (12V) 1-30A(6V) | 1A | 1% |

| Discharge current | 1-100A(2V) 1-30A(12V ) 1-30A(6V) | 1A | 1% |

| Total charging voltage | 1.7-2.4V(2V) 5.4-7.2V(6V) 10.2-15V(12V) | 0.1V | 0.25% |

| Total discharging voltage | 1.7-2.4V(2V) 5.4-7.2V(6V) 10.2-15V(12V) | 0.1V | 0.25% |

| Power supply | AC220V±10% | ||

| LCD display | 192*64/ 128*64 | ||

| Temperature | 5℃~50℃ | ||

| Humidity | 5%~90%RH | ||

| Dimension | 395*370*200 mm | ||

| Weight | 10Kg | ||

| Communication | USB interface | ||

Battery Internal Resistance Tester

The IR3915 battery internal resistance tester is a new product generation for internal resistance with touch screen operation. It is specially designed to evaluate and maintain all stationary power systems including uninterruptible power system.

With accurately testing battery internal resistance and voltage, the battery internal resistance tester gives an indication of battery capacity and technical status, for new cells combinations or identifying lag-out cells. The battery internal resistance tester has key-board and touch screen operation methods; it can carry out both group test and single cell tests.

Technical Parameters of the Battery Internal Resistance Tester

| Item | Parameter | |

| Test range | Internal resistance | 0~100mΩ |

| Voltage | 0~220V | |

| Resolution ratio | Internal resistance | 0.1mΩ |

| Voltage | 1mV | |

| Test precision | Internal resistance | ±1.0% reading ±6 |

| Voltage | ±0.2% reading ±6 | |

| LCD display | 320*240 | |

| Power supply | Lithium ion battery, rechargeable, more than 8 hours length | |

| Measuring data memory | 3000 cells | |

| Com port | USB | |

| Dimension | 190 x 100 x 30mm | |

| Weight | 0.5kg | |

We provide all equipment related with lead-acid battery manufacturing and testing.

English

English Español

Español Русский

Русский Português

Português Français

Français