Car Radiator Making Machine

Our company can provide a complete lineup of machines for car radiator production, such as aluminum fin rolling machine, high frequency aluminum tube mill, radiator core builder, continuous brazing furnace, water tank clinching machine, radiator leakage tester, etc.

We also have machines for automotive AC condenser & evaporator production, such as header pipe punching machine, header pipe grooving machine, microchannel tube straightening & cutting machine, microchannel serpentine tube bender, condenser core assembling machine, etc.

We have all related machines & equipment for your radiator, condenser, evaporator, intercooler, oil cooler, heater, etc.

-

- Aluminum Radiator Fin Forming Machine

This fin forming machine is specially designed for forming aluminum foil coil into wave-type radiator fin continuously.

This fin forming machine offers PLC control, HMI operation, auto decoiling, feeding, forming, wave fixing and cutting, simple and highly efficient.

-

- Aluminum Radiator Tube Mill (High Frequency)<)

This series of high frequency aluminum radiator tube mills is capable of producing aluminum radiator flat tubes, condenser/evaporator header pipes, intercooler flat tubes, etc.

-

- Radiator Folded B Type Tube Mill

This tube mill is specially designed for producing folded B type radiator aluminum flat tubes.

The folded tubes are produced from brazing sheet coils by a multi-step roll forming process – bringing the sheet gradually into a “B” shape.

-

- Matrix Radiator Core Builder

This martrix core builder is mostly for OEM radiator / condenser manufacturers as it can normally produce 60 cores per hour.

-

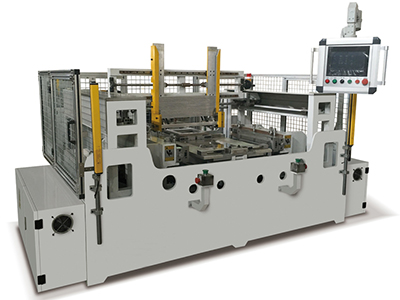

- Radiator Core Builder

For car radiator core assembly, there are several options in different automation levels: - Full servo clamping & header plates fitting with automatic tube dispenser

- Full servo clamping & header plate fitting with manual-pushing dispenser

- Servo clamping and pneumatic header plate fitting

- Full pneumatic clamping & header plate fitting

- Single-row, double-row, four-row machines

- With / without flat tube flaring function

-

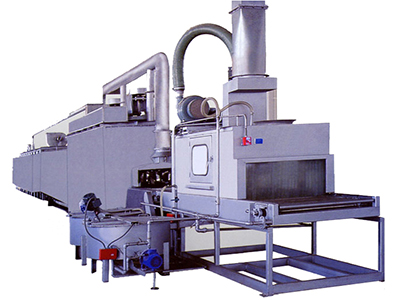

- Continuous Nitrogen Shielded Brazing Furnace

By using non-corrosive flux (Nocolok Flux) under Nitrogen gas shield protection, this oven is capable for brazing all kind aluminum heat exchanger cores, such as car radiator, car AC condenser & evaporator, heater, oil cooler, intercooler, etc.

Our design is advanced, state-of-the-act, mature, wear well, environmentally-friendly.

-

- Radiator Water Tank Clinching Machine

The radiator water tank clinching machine is for crimping plastic water tanks to brazed radiator cores.

Full automatic clinching machine: finish crimping long edges and short edges in one cycle without manual operation. Two stations are mounted together.

-

- Radiator Leakage Tester

This radiator leakage tester is specially designed for testing air tightness of automotive radiator cores.

Testing pressure range is 50~400KPa.

Double-station testing can raise your efficiency well.

-

- Aluminum Microchannel Tube Straightening & Cutting Machine

Parallel-flow condenser in automotive air conditioner uses microchannel flat aluminum tube which is also called as multiport tube.

This tube straightening and cutting machine is specially designed for decoiling reel shaped microchannel aluminum tube automatically.

-

- Aluminum Microchannel Tube Serpentine Bending Machine

This bending machine is for bending microchannel flat tubes into serpentine shape for parallel-flow condensers and evaporators.

This machine is PLC control, HMI operation. Feeding length and bend quantity can be preset on the touch screen and the program can be saved for future use.

-

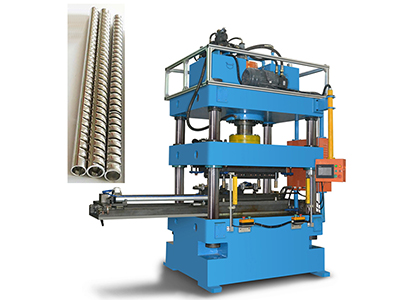

- Condenser Header Pipe Punching Machine

The hydraulic system adopts big-flow plug-in valves, high speed, stable running.

This condenser header pipe punching machine is PLC control, HMI operation. Manually inserting aluminum pipe onto core axis, pressing down start button, the machine will automatically position, insert core axis, clamp, lubricate, punch, shock, draw core axis, raise and automatic release finished header pipe.

-

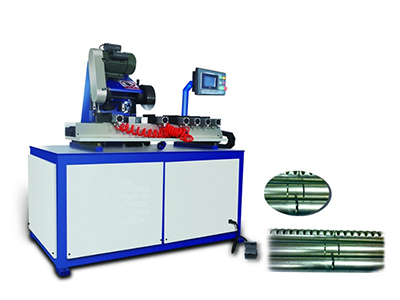

- Condenser Header Pipe Grooving Machine

This condenser header pipe grooving machine is specially designed for slotting grooves on header pipes.

This machine is servo motor feeding, PLC control, touch screen operation, full automatic (except for manual clamping and unloading). Groove numbers and distance between every groove can be preset.

English

English Español

Español Русский

Русский Português

Português Français

Français