- Home

- Products

- Car Radiator Making Machine

- Aluminum Microchannel Tube Serpentine Bending Machine

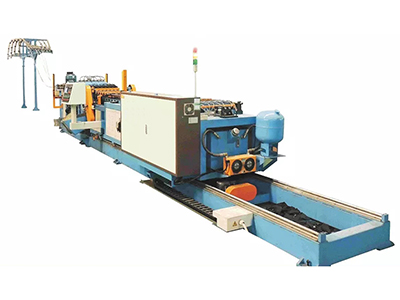

Aluminum Microchannel Tube Serpentine Bending Machine

This machine is specially for bending multiport / microchannel flat aluminum tubes into a serpentine shape for condensers and evaporators. It is comprised of a coil tube pay off strand, a straightening device, an automatic feeding device, an automatic bending head, and a stretch cutting device. It features PLC control and HMI operation, allowing the feeding length, bending radius and bending quantity to be preset on the touch screen. Also the parameters can be easily set and saved for future use. A high repositioning accuracy is guaranteed due to servo motor feeding and ball screw transmission.

The microchannel tube is also called a multiport tube, used in parallel-flow condensers and evaporators. This machine is for bending microchannel flat tubes into serpentine shape.

Main Technical Data of Aluminum Microchannel Tube Serpentine Bending Machine| Item | Data |

| Suitable multiport flat aluminum tube | Width 16-32mm x thickness 1.3-3.0mm |

| Suitable flat tube reels | ID 300~600mm, OD max. 1200mm, height 400mm, weight 500kg |

| Suitable core length | 120-680mm |

| Max. bending quantity | 50 |

| Length feeding accuracy | ±0.25mm |

| Finished part levelness | Less than 1mm |

| Pneumatic pressure | 0.5MPa |

| Total motor power | 4.5kW |

| Production speed | 90-150 seconds (feeding, bending, cutting @250mmx17 bends) |

| Productivity | 250 cores per shift (@250mmx17 bends) |

| Main machine | About 1500kg |

| Pay-off | About 1100kg |

| Main machine | About 4500 x 2000 x 1750mm |

| Pay-off | About 1800 x 2200 x 1800mm |

| Line occupation | About 15m x 1.5m x 1.7m (L x W x H) |

English

English Español

Español Русский

Русский Português

Português Français

Français