- Home

- Products

- Car Radiator Making Machine

- Aluminum Microchannel Tube Straightening & Cutting Machine

Aluminum Microchannel Tube Straightening & Cutting Machine

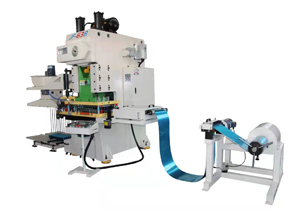

Description of Aluminum Microchannel Tube Straightening & Cutting MachineParallel-flow condenser in automotive air conditioner uses microchannel flat aluminum tube which is also called as multiport tube.

This tube straightening and cutting machine is specially designed for decoiling reel shaped microchannel aluminum tube automatically.

This machine adopts special nicking cutting technology, burrless and very small deformation on cutting section.

And the machine has special function for shrinking tube ends which is good for further core assembling.

This machine can cut two microchannel aluminum tubes simultaneously.

- Servo feeding, stable and high re-positioning precision

- One time cutting two pieces, high efficient

- With special stretch-breaking cutting function, burrless cutting

- PLC control, high automation – auto decoiling, auto feeding, auto cutting.

| Item | Data |

| Suitable material | Microchannel aluminum tube |

| Microchannel tube width | 12-32mm |

| Microchannel tube thickness | 1.2-3mm |

| Microchannel tube coil size | Outer diameter: 1200mm Inner diameter: 450-500mm Height: 300-350mm Weight: max. 300kg |

| Cutting pieces | 2 |

| Cutting length | Min. 100 mm, no max. limit |

| One-time feeding stroke | 200-900 mm |

| Cutting speed | 15~22 cuts per minute (@500mm length) |

| Cut-to-length precision | ≤ ±0.2mm (@ 500mm length) |

| Straightening width error | Less than 0.02mm |

| Straightening thickness error | Less than 0.04mm |

| Straightening precision in width direction | Less than 0.4 / 800mm |

| Straightening precision in thickness direction | Less than 0.8 / 800mm |

| Duration for changing cutting blade | ≤ 5min |

| Duration for changing tube width | ≤ 15min |

| Total electric power | About 5kW |

| Air source | 0.5-0.7MPa |

| Total weight | About 3000kg |

| Main machine dimension | About 6000 x 850 x 700mm |

Inquiry Form

English

English Español

Español Русский

Русский Português

Português Français

Français