- Home

- Products

- Car Radiator Making Machine

- Condenser Header Pipe Punching Machine

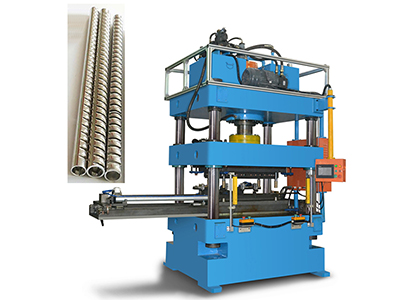

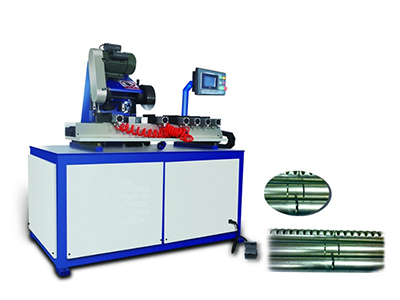

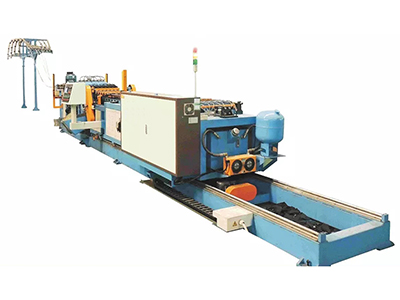

Condenser Header Pipe Punching Machine

The hydraulic system adopts big-flow plug-in valves, high speed, stable running.

This condenser header pipe punching machine is PLC control, HMI operation. Manually inserting aluminum pipe onto core axis, pressing down start button, the machine will automatically position, insert core axis, clamp, lubricate, punch, shock, draw core axis, raise and automatic release finished header pipe.

Light curtain protection system ensures safe operation.

| Item | Data |

| Machine code | JLG-Y900 |

| Max. working force | 60T |

| Pipe quantity can be produced one time | One |

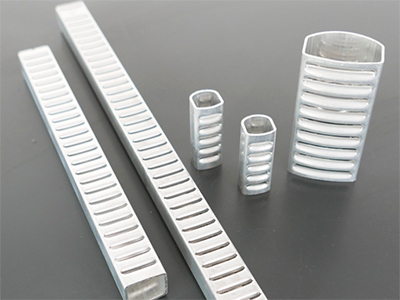

| Suitable material | Aluminum or copper |

| Suitable pipe diameter and wall thickness | Φ30mm x (1.0~1.6)mm |

| Suitable pipe effective length | 100~600mm |

| Pierced slot width and tolerance | 1.0~3 ± 0.03 mm |

| Pierced slot length and tolerance | 16~36 ± 0.03mm |

| Center distance between slots and tolerance | 5~12 ± 0.05mm |

| Production speed | About 20 seconds per piece |

| Die changing speed | About 30 minutes |

| Hydraulic pressure | 8~21MPa |

| Pneumatic pressure | 0.5~0.8MPa |

| Hydraulic oil | ISO VG32 for winter; ISO VG46 for Summer |

| Lubricant oil | ISO VG22-32 |

| Total motor power | 7.2kW |

| Machine dimension | 2800 x 2100 x 2750mm |

| Machine weight | Total 4200kg |

Inquiry Form

English

English Español

Español Русский

Русский Português

Português Français

Français