- Home

- Products

- Car Radiator Making Machine

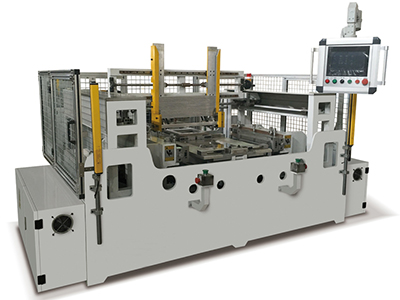

- Aluminum Radiator Tube Mill (High Frequency)<)

Aluminum Radiator Tube Mill (High Frequency)<)

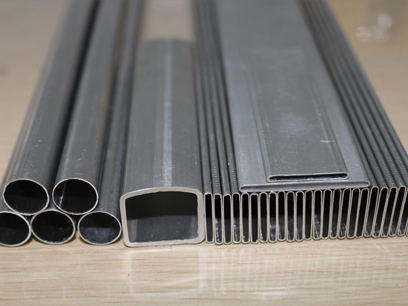

Description of High Frequency Aluminum Radiator Tube MillThis series of high frequency aluminum radiator tube mills is capable of producing aluminum radiator flat tubes, condenser/evaporator header pipes, intercooler flat tubes, etc.

Our tube mills can 100% replace those aluminum pipe mills from Schoeler Germany, Millmaster USA, or Japan.

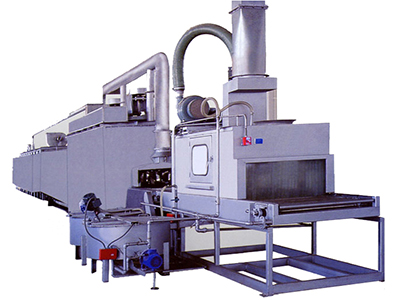

Production Flow of High Frequency Aluminum Radiator Tube Mill- Aluminum strip reel loading by vacuum absorber loading device (optional)

- Aluminum strip decoiling by active decoiler

- Aluminum strip feeding by synchronization feeder with buffer

- Pre-forming by pre-forming mould section

- Welding by solid-state high-frequency welder

- Squeezing by ceramic rollers

- Burr removing

- Size fixing by size-fixing mould section

- Cutting to length by non-stop flying saw cutter

- Special roller designing and adjusting technology for various aluminum tube forming.

- Max. production speed 150m/min

- High quality solid state high-frequency welder, less electric consumption, smaller internal burr

- Online cut-to-length, no need secondary processing

- Special cutting device, supper high speed cutting catching the whole line speed

- 300~375 cuts/min @400mm length

- 160~200 cuts/min @750mm length

- 120~150 cuts/min @1000mm length

- 40~50 cuts/min @3000mm length

- 20~25 cuts/min @6000mm length

| Item | Data |

| Suitable material | Pure aluminum or aluminum alloy 4343/3003/7072 or 4343/3005/7072, with/without cladding |

| Applicable flat aluminum tube size | Width: 16~32mm Thickness: 1.8~2.2mm Wall thickness: 0.26~0.30mm |

| Suitable aluminum pipe length | 300~6000mm |

| Applicable aluminum strip coil size | Max. OD: 1900mm ID: 290~310mm Max. Weight: 900kg |

| Production speed | Max. 150m/min |

| Cutting speed | Max. 400 cuts per minute |

| Cooling method for welder | Air cooler + water chiller |

| Cooling method for rollers | Recycling liquid type coolant |

| Transmitting method | Coupling + reducer distributors |

| Tube bow | ≤0.5mm @500mm length |

| Tube twist | ≤0.3mm @300mm length |

| Cutting end inclination | ≤0.3mm |

| Cutting burr height | ≤0.08mm |

| Cut-to-length precision | ≤ ±0.3mm |

| Life of cutting blades | More than 0.2 billion cuts |

| Duration for changing rollers | One hour by 4 workers @ cassette changing method |

| Duration for changing tube width | ≤ 15min |

| High-frequency power | 400kHz, 100kVA |

| Total electric power | About 160kVA |

| Total electric consumption | About 80 kW·h |

| Air source | 0.5-0.7MPa, 0.8m3/min |

| Noise level | ≤78dB (@2m away) |

| Pollution | Welding smoke & dust collecting, no liquid pollution discharged |

| Total weight | About 16 Tons |

| Whole line dimension | About 30m x 5m x 3.5m (including run-out rack) |

Inquiry Form

English

English Español

Español Русский

Русский Português

Português Français

Français