Punching, Cutting, Bending Machines

Besides roll forming machines & duct machines, we have another category of machine tools for metal punching, cutting, bending, such as hydraulic press brake, roller bending machine, Ironworker, hydraulic shear, CNC plasma cutting machine, CNC laser cutting machine, water jet cutting machine and busbar bending punching cutting machine, etc.

-

- Hydraulic Press Brake

This hydraulic press brake is normal numeric control, without CNC control system. The adjustment of backgauge and ram stroke is manual.

Steel-welded construction, vibration to eliminate stress, with high strength and good rigidity.

Hydraulic top-drive, steadiness and reliability.

-

- Hydraulic Shear

This hydraulic shear is installed with a motor-drive back gauge device with manual fine-adjusting, numerical displayed. A synchronous pneumatic loading car is for your choice.

The frame is welded with sufficient strength and rigidity

This hydraulic shear is equipped with a mechanism for quick adjusting blade clearance

-

- Roller Bending Machine

This roller bending machine is a primary product of our company. When pre-bending end, the length of flat edge can be set freely. And the top roller can move up and down. Drum-type upper roller is suitable for wider plate thickness range.

High precision end pre-bending

-

- Ironworker

Ironworker has two kinds: hydraulic ironworker and mechanic ironworker. It combines the functions of punching, shearing, pressing and folding into one body.

Type: Q35Y-16, Q35Y-20, Q35Y-25

Pressure (Ton)L: 55, 75, 110

-

- Hydraulic Press

Four-column structure, simple and economical

Hydraulic system adopts pin-fit valve integration system, with the advantages of reliable action, long life, small hydraulic impact, no leakage.

Electric control system is separate. You can pre-set fixed stroke or fixed pressure.

-

- Mechanical Press

The JL21 stroke adjustable press comes with welded body for high intensity.

The mechanical press is installed with dry type pneumatic friction clutch.

Users can adjust the sliding block stroke through the air cylinder.

In addition to the eight-face slide guide, this range of product is equipped with overload protection device.

-

- Friction Press

The friction press is a kind of universal pressing machine for diversified applications. Our friction screw press is widely employed for stamping, upset forging, bending, rectifying, fine pressing, among others.

-

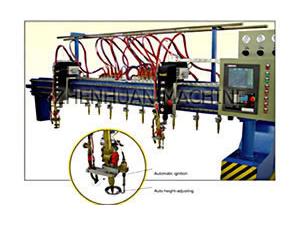

- CNC Plasma Cutting Machine

This CNC plasma cutting machine can be designed and manufactured according to customer's requirements. Different plasma power for different thickness, different cutting length and width, different control systems and quantity of plasma or flame cutting torches are available.

-

- Water Jet Cutting Machine

This cutting machine is free of heat-affected zone (HAZ) or heat distortion.

It provides easy control, high accuracy and excellent edge finishing without frayed edges or burrs.

Small kerf size (usually less than 1.2mm), low waste.

This water jet cutting machine can cut almost all kind of materials, even sandwich panels.

-

- CNC Turret Punch Press

The CNC turret punch press possesses good performance, high efficiency, and convenient operation. It is ideal for automotive, decoration, processing, and electric power industries. With the adoption of CNC technology, this equipment enables the workpiece to be deposited accurately and quickly. It can automatically choose the tools in the turret for punching holes with different sizes, shapes, and distances.

-

- Turret Punch Press Tool Grinding Machine

Our grinding machine is specially designed for grinding the punching tools that are used in a turret punch press. The maximum grinding diameter is up to 300mm. The available rotary table will offer a 0 and 15 degree incline, when it is utilized for cutting rooftop tools (one kind of punching tools).

-

- CNC Rebar Stirrup Bending Machine

As the name suggests, our CNC rebar stirrup bending machine is extensively seen in bending rebar and stirrup for reinforced concrete. Our stirrup bender is fully automatic. Equipped with HMI, the rebar bender supports parameter preset, such as rebar and stirrups shape, size, and quantity.

English

English Español

Español Русский

Русский Português

Português Français

Français