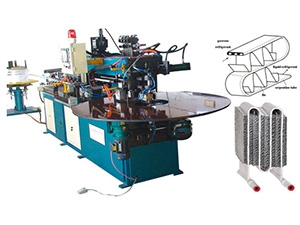

Microchannel Multiport Aluminum Serpentine Tube Bending Machine

This product has been discontinued and removed from our shelves.

This machine is specially for bending multiport / microchannel flat aluminum tubes into a serpentine shape for condensers and evaporators. It is comprised of a coil tube pay off strand, a straightening device, an automatic feeding device, an automatic bending head, and a stretch cutting device. It features PLC control and HMI operation, allowing the feeding length, bending radius and bending quantity to be preset on the touch screen. Also the parameters can be easily set and saved for future use. A high repositioning accuracy is guaranteed due to servo motor feeding and ball screw transmission.

Technical Data

| Item | Data |

| Suitable multiport flat aluminum tube | Width 19-44mm x thickness 4, 5, 6mm |

| Suitable flat tube reels | ID 500mm, OD 1100mm, height 400mm |

| Core length | 250-850mm |

| Max. bending quantity | 50 |

| Pneumatic pressure | 0.6MPa |

| Hydraulic pressure | 5MPa |

| Total motor power | 7.5kW |

| Productivity | 220 cores per shift |

| Machine weight | About 3000kg |

| Machine dimension | About 15000 x 2400 x 1900mm |

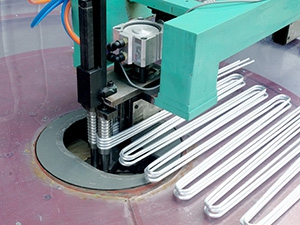

Round Metal Serpentine Tube Bending Machine

The round metal serpentine tube bending machine is specially designed to bend multiple round copper, aluminum or steel tubes into a serpentine tube.

The machine includes an automatic feeding device, an automatic bending head and a PLC control system. It is PLC controlled with HMI operation. The feeding length, bending radius and bend quantity can be preset on the touch screen, and numerous programs can be saved for future use.

Technical Data

| Item | Data |

| Suitable copper tube material | T2M or T2Y2 |

| Suitable copper tube diameter | Φ4.75~9.52mm |

| Suitable copper tube thickness | 0.22+0.15mm |

| Bending radius | R40 (min. R20) |

| Bending angle | 0-190º |

| Max. copper tube length | 8000mm |

| Max. bending quantity | 10 |

| Feeding speed | 400mm/s |

| Bending speed | 180º/s |

| Composite bending efficiency | 3~4 seconds per bend |

| Bending axis repositioning accuracy | ±0.5º |

| Feeding axis repositioning accuracy | ±0.1mm |

| Pneumatic pressure source | 0.6MPa |

| Total motor power | 2kW (three servo motors) |

| Machine weight | About 3000kg |

| Machine dimension | About 2200 x1100 x 1580mm |

Note: The machine can be designed with coil tube decoiling, straightening and cutting devices.

English

English Español

Español Русский

Русский Português

Português Français

Français