- Home

- Products

- Pipe / Tube Forming Machine

- Steel Tube (Cylinder) Necking-in & Closing Machine

Steel Tube Necking-in & Closing Machine

Description

The steel tube necking-in and closing machine uses hot spinning technology, primarily for necking-in and closing of steel tubes and pipes, especially in automotive shock absorber, motorcycle vibration dampers, SCBA cylinders, accumulator shells, small gas storage cylinders, boiler tubes, and chemical pipe industries.

Main Features

-OMRON PLC control and Weinview touch screen operation

- Induction heating method, clean & quick

- Both necking-in and closing: The reserved hole diameter after necking-in can be freely adjusted, and the end wall thickness after closing can be increased for better pressure resistance with no need for additional welding.

- Closing end can be flat, spherical, ellipsoidal or pyramid shaped, and is easy to adjust.

- Automatic hydraulic clamping

- Necking-in & closing dies are made using a cobalt-base alloy. They are resistant to high temperatures, and feature a long service life.

- Compulsive lubricating system, prolonging life of dies

- Auto loading & unloading device is optional

Technical Data

| Item | RXYJ-40 | RXYJ-70 | RXYJ-80 |

| Suitable tube diameter | 14-40mm | 20-70mm | 30-80mm |

| Suitable tube wall thickness | 1-2.5mm | 1-5mm | 1-4mm |

| Suitable tube length | 80-600mm | 80-600mm | 120-500mm |

| Necking-in / closing speed | 5~15s | ||

| Production speed | 200~400pcs/h | 100~300 pcs/h | |

| Main motor power | 5.5kW | 6.5kW | 8.5kW |

| Induction heating power | 25kW | 35kW | 35kW |

| Machine dimension | 1500x2200x1600mm | 1600x2250x2050mm | 3000x2800x2200mm |

| Machine weight | 1850kg | 2000kg | 3500kg |

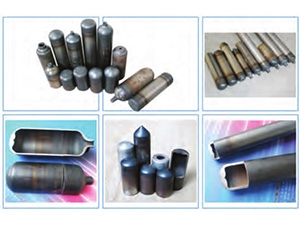

Typical Products Made by Steel Tube Necking-In & Closing Machine

Stainless Steel Sensor Tube Closing Machine

Description

The stainless steel sensor tube closing machine is specially designed to close stainless steel sensor tube ends. It can also be used for necking-in purposes. The closed mouth diameter can be freely adjusted, and the machine is capable of closing the ends of both steel and copper tubes.

Technical Data

| No. | Item | Data |

| 1 | Suitable stainless steel tube diameter | 5-10mm |

| 2 | Suitable stainless steel tube wall thickness | 0.4-1.0mm |

| 3 | Suitable stainless steel tube length | Less than 500mm |

| 4 | Spinning method | Cold spinning |

| 5 | Closed end shape | Spherical and ellipsoidal |

| 6 | Motor power | 3kW |

| 7 | Production speed | 300-500 pcs/h |

| 8 | Closing tool material | Carbide alloy |

| 9 | Machine dimension | About 1000 x 1300 x 1550mm |

| 10 | Machine weight | About 750kg |

Typical Sensor Tubes Made by This Tube Closing Machine

We have a variety of tube necking-in and closing machines available for different purposes.

English

English Español

Español Русский

Русский Português

Português Français

Français