- Home

- Products

- Pipe / Tube Forming Machine

- Oval Tube Finning Machine

Oval Tube Finning Machine

Heat Exchanging Oval Tube Finning Machine

Description

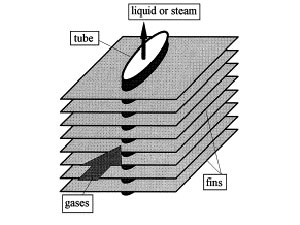

The heat exchanging oval tube finning machines are widely used in air cooling systems of power station and chemical plant. The tubes use an oval tube as a carrier, which is different to other traditional cooler fin tubes.

The oval tube finning machine is specially designed to punch and string fins automatically onto the oval tubes.

Main Features

- PLC control, HMI operation, display of working conditions

- The electronic cam & phase display ensures accurate and smooth actions between the punch press and stringing device.

- The die table moves transversally, making the die maintaining and checking convenient.

- More roller guides, higher guiding precision, longer die life

- Powerful inverter speed control, stable operation of entire production line

Technical Data

| Item | JG31CT-45 | JG31CT-100 |

| Nominal force (kN) | 450 | 1000 |

| Ram stroke (mm) | 70 | 70 |

| Upper mold adjustment (mm) | 50 | 80 |

| Die height (mm) | 2750 | 270 |

| Die height adjustment (mm) | 20 | 30 |

| Number of strokes (times/min) | 60-250 | 60-250 |

| Suitable band width (mm) | 150 | 240 |

| Suitable coil OD. (mm) | 1200 | 1200 |

| Suitable coil weight (kg) | 1000kg | 1000kg |

| Max. oval tube length (mm) | 10m | 15m |

| Max. numbers of tube stringing | 2 or 4 | 8 or 4 |

| Main driving motor power (kW) | 5.5 | 11 |

Photos of Typical Oval Fin Tubes

English

English Español

Español Русский

Русский Português

Português Français

Français