- Home

- Products

- Pipe / Tube Forming Machine

- Extruded Fin Tube Machine

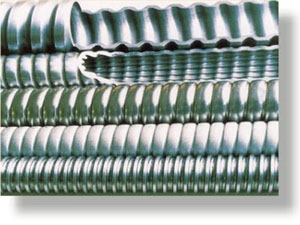

Extruded Fin Tube Machine

Description of Extruded Fin Tube Machine

An extruded fin tube machine is also called a tube finning machine, extruded high fin tube machine and extruded low fin tube machine.

1.Tool holder and its body adopt the advanced dual-circular key structure to withstand torque and achieve accurate and reliable displacement.

2.Tool holder adopts split type design, making blade installation, debugging and cleaning operations easier.

3.Spindle bearing can be moved using conical hydrodynamic sliding bearings, bearing to maximize the utilization.

4.Universal joints and shaft key link between all lines of Hot Pepper. Cooling box is separated from rolling mill machine.

5.Closely with technical data, rolling fin efficiently, durable blades.

Technical Parameters of Extruded Fin Tube Machine

| Item | Specifications | ||

| GJ-66A | GJ-66B | GJ-66C | |

| Base tube material | Aluminum, carbon steel, copper | ||

| Base tube diameter range | Φ7~12mm | Φ12~32mm | Φ15~45mm |

| Fin material | Aluminum / copper | ||

| Fin thickness | 0.3~0.7mm | ||

| Fin height | 7mm | 16mm | 16mm |

| Finished finned tube outer diameter | Φ25mm | Φ64mm | Φ77mm |

| Spiral pitch | 1.8mm; 2.0mm; 2.1mm; 2.3mm; 2.5mm; 2.8mm; 3.0mm; 3.2mm~8.0mm** | ||

| Max. length of finished finned tube | 15m | ||

| Output spindle rotating speed | 80rpm, 100rpm, 120rpm | ||

| Fin rolling speed | 0.6m/min, 0.75m/min, 0.9m/min | ||

| Main drive motor power | 11kW | ||

| Machine weight | About 1920kg | ||

| Overall dimension | About 2050×760×1430mm | ||

Note:

*When base tube diameter is less than 22mm, recommend fin height shall be not higher than 12mm.

*When fin pitch is less than 2.3mm or more than 3.2mm, it’s better to provide more details of fin tubes for us to check.

L-shape, LL-shape Finning Tube Winding Machine

This machine is special designed for processing L/ LL shape finned tubes in different diameters. It adopts numerical tension control to keep the binding force between tube and fin being in the best state!

Technical Parameters of L-shape, LL-shape Finned Tube Winding Machine

| Item | Specifications | |

| Base tube diameter | Φ16-38mm | |

| Base tube material | Stainless steel, carbon steel, copper, aluminum | |

| Fin material | Aluminum | Fin height≤20mm, fin pitch 2.0-10mm |

| Copper | Fin height≤12mm, fin pitch≤2.54mm | |

| Fin thickness | 0.4-1.0mm | |

| Main driving motor power | 5.5kW | |

| Production speed | Max. 700rpm, about 1.5m/min (based on base tube diameter) |

|

L Fin Tube Winding Machine

This L fin tube making machine is specially designed for winding spiral fin to base tube to form L-shaped finned tubes in different diameters.

Technical Parameters of L Fin Tube Winding Machine

| Item | Specifications |

| Fin material | Aluminum, fin height≤16mm, fin pitch 2.0-10mm Copper, fin height≤12mm, fin pitch≤2.54mm |

| Base tube material | stainless steel, carbon steel, copper, aluminum |

| Base tube diameter | Φ16-38mm* |

| Fin thickness | 0.4-1.0mm |

| Motor power | 2.2kW, 3-phase |

| Max. winding speed | Spindle speed 700rpm/min |

| General productivity | About 250m per 8 hours |

| Machine dimension (packing) | 1350 x 650 x 1250mm |

| Machine weight | About 400kg |

Note: When base tube diameter is 13mm or 12mm, the finished fin height is not higher than 9mm.

English

English Español

Español Русский

Русский Português

Português Français

Français