- Home

- Products

- Pipe / Tube Forming Machine

- Steel Tube / Pipe Punching Machine

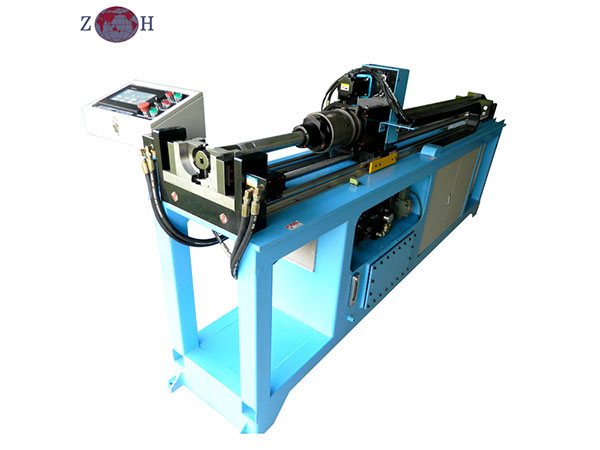

Steel Tube / Pipe Punching Machine

Description

We are a professional manufacturer for round / square / rectangular tube pipe punching machines. Our product can be specially designed according to the customer needs.

Main Features of Tube Pipe Punching Machine

1. Servo feeding, high precision

2. Hole position can be preset on HMI

3. Hydraulic driven, low noise

4. PLC control, HMI operation, full automatic

Main Technical Specifications of Tube Pipe Punching Machine

| Item | Specifications |

| Applicable tube/pipe material | Iron, copper, aluminum |

| Square/rectangular tube/pipe size | As per requirement |

| Tube/pipe wall thickness | Max. 2mm (or customized) |

| Max. tube/pipe length | As per requirement |

| Min. distance between hole centers | Round hole: 30mm, square hole: 35mm. |

| Accuracy of hole position | ±0.3mm |

| Punching speed | 4 seconds per hole |

Punching tooling is equipped to punch holes on aluminum pipes or aluminum profiles:

There is round pipe punching machine which is capable of punching holes at any position of the pipe:

| Item | Specifications |

| Max. pipe length | 1600mm (customized) |

| Suitable carbon steel pipe diameter | Max. 54mm (customized) |

| Suitable carbon steel pipe wall thickness | Max. 2.5mm (customized) |

| The space between tube end and the latest hole | Min. 50mm |

| Hole positioning precision | ±0.2mm |

| Working efficiency | 1~3 seconds per hole |

| Operation method | Automatic / manual |

| Workpiece loading method | manual |

| Control method | PLC + 5.7" HMI |

| Clamping power | Hydraulic |

| Punching power | Hydraulic |

| Hydraulic pressure | 7MPa |

| Punching force | 12tons |

There is stainless steel pipe flange hole punching machine which is capable of punching collar holes:

We can also customize special collar hole punching machine according to customer needs:

English

English Español

Español Русский

Русский Português

Português Français

Français