Automobile Radiator Making Machine

This product has been discontinued and removed from our shelves.

Automobile radiators are also called water tanks. In order to produce high quality automobile tanks, the following machines are needed:

Radiator Fin Forming (Rolling) Machine

Microchannel Flat Aluminum Tube Cutting Machine

Header Pipe Punching Machine

The hydraulic system uses large-flow plug in valves, and features high speed and stable operation. It has the functions of PLC control, digital display, as well as manual loading, automatic piercing and automatic unloading. With a light curtain protection system, the operation safety is guaranteed.

Technical Data

| Item | Data |

| Model | JLG-1 (/JLG-2) |

| Max. working force | 65T (/100T) |

| Pipe quantity can be produced one time | One (/Two) |

| Suitable material | Aluminum or copper |

| Suitable pipe diameter and wall thickness | Φ(20~50)mm x (1.0~1.5)mm |

| Suitable pipe effective length | 200~650mm |

| Pierced slot width and tolerance | 1.0~3 ± 0.03 mm |

| Pierced slot length and tolerance | 16~36 ± 0.03mm |

| Center distance between slots and tolerance | 5~12 ± 0.05mm |

| Production speed | About 20 seconds per pipe |

| Die changing speed | About 30 minutes |

| Total motor power | 11.5kW |

| Machine dimension | 2250 x 2080 x 2480mm |

| Machine weight | 4T / 6T |

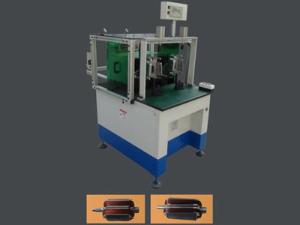

Radiator Auto Core Builder

The radiator auto core builder is designed to automatically assemble the cores of automobile water tanks. It can automatically load, order and clamp flat tubes as well as assemble header plates.

Features

- Universal chassis adapting to cores in various sizes

- X-axis motion is controlled by step motor

- Automatic header plate assembly

- For getting different pitch, just change the pitch control tooling

- PLC control + HMI operation

Technical Data

| Item | Data | |

| Suitable flat tube length | 350-800mm | |

| Max. flat tube numbers | 60 | |

| Suitable flat tube width | 16~26mm | |

| Suitable flat tube thickness | 2mm | |

| Flat tube pitch | 10mm | |

| Suitable fin height | 8mm | |

| Suitable fin width | Same as width of flat tube | |

| Distance between fin and header plate | 10mm | |

| Core building precision | Length & height | ± 1mm |

| Diagonal length | ±1.5mm | |

| Flat tube loading speed | ≦2 pcs/s | |

| Loading cycle duration | About 120s | |

| Flat tube storage capacity | About 300pcs | |

| Total motor power | 4.5kW | |

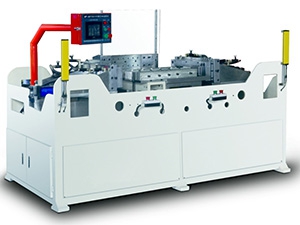

Auto Tank Clinching Machine

The fully automatic radiator tank clinching machine is a state of the art designed for clinching plastic tanks to the main plate of the radiator. The machine has two workstations, which work simultaneously to clinch both sides together, and thus, increasing the production efficiency. It is fully automatic, and suitable for most existing water tank types.

Technical Data

| Item | Data |

| Suitable max. core size | 1000 x 850mm |

| Suitable max. header plate size | 1000 x 100mm |

| Suitable max. height of radiator | 120mm |

| Suitable teeth pitch | Adjustable, default 10mm |

| Suitable max. teeth numbers | 100 |

| Clinch speed | 1-20 times per minute |

| Total power | 2.5kW, single phase, AC 50Hz |

Aluminum Brazing Furnace

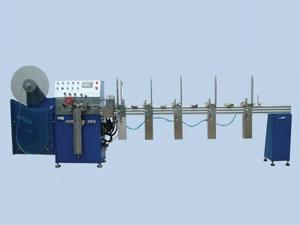

The brazing furnace is a specialized piece of brazing equipment that uses a non-corrosive flux through nitrogen shielding. It is widely used for the production of aluminum/copper heat exchangers, and is suitable for nitrogen shielding brazing of evaporators, condensers, intermediate coolers, water tanks and more.

Technical Data

| Model | Rated Power | Rated Temp. | Suitable workpiece dimension(mm) | Length of brazing section | Whole line length |

| NB-450-150 | 242KW | 750ºC | 450 x 150 | 6m | 28.5m |

| NB-450-200 | 242KW | 750ºC | 450 x 200 | 6m | 28.5m |

| NB-600-200 | 303KW | 750ºC | 600 x 200 | 8m | 29m |

| NB-600-300 | 303KW | 750ºC | 600 x 300 | 8m | 29m |

| NB-800-200 | 515KW | 750ºC | 800 x 200 | 11m | 37.7m |

| NB-800-300 | 515KW | 750ºC | 800 x 300 | 11m | 37.7m |

| NB-1000-200 | 615KW | 750ºC | 1000 x 200 | 11m | 37.7m |

| NB-1000-300 | 615KW | 750ºC | 1000 x 300 | 11m | 37.7m |

| NB1100-200 | 655KW | 750ºC | 1100 x 200 | 11m | 37.7m |

| NB-1100-350 | 685KW | 750ºC | 1100 x 350 | 11m | 37.7m |

| NB-1200-200 | 715KW | 750ºC | 1200 x 200 | 11m | 37.7m |

| NB-1200-350 | 735KW | 750ºC | 1200 x 350 | 11m | 37.7m |

Note: The length of the brazing section can be customized according to customer requirements.

English

English Español

Español Русский

Русский Português

Português Français

Français