- Home

- Products

- Roll Forming Machine

- K Span Roll Forming Machine

MIC-240 Super K Span Roll Forming Machine

Description of MIC-240 Super K Span Roll Forming Machine:

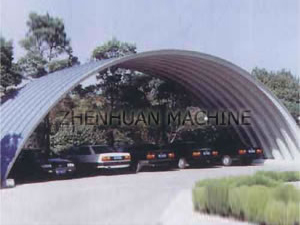

This roll forming machine is widely used in the construction of factories, garages, hangars, stadiums, exhibition halls, theaters, and so on.

This MIC-240 super K span machine developed by us adopts the same technology with ABM MIC-240 forming machine. It is comprised of mechanical expansion decoiler, straight panel forming unit, hydraulic / electric mould cutting device, curving panel forming unit, control system, run-out racks for straight, curve panels and all other accessories and tools. For all parts are installed on a mobile chassis, our super K span roll forming machine is ideal for site working.

Features of MIC-240 Super K Span Roll Forming Machine:

1 Rollers are made of good steel, coated with rigid chrome.

2 The rubber feeding device of it can feed 0.5-1.5mm color steel sheets.

3 Light and convenient hoist, only 2kg (those from USA are 30kg). So quick and convenient installation is possible.

4 Large span, high corrugation, high tension strength, without nuts.

5. During production, it is unnecessary for you to adjust the clearance between top and bottom rollers.

Applications of MIC-240 Super K Span Roll Forming Machine

This roll forming machine is widely used in the construction of factories, garages, hangars, stadiums, exhibition halls, theaters, and so on.

Main Technical Data of MIC-240 Super K Span Roll Forming Machine:

| Mounting dimension | 8900mm x 2300mm x 2500mm |

| Total weight | about 10500kg |

| Control system | electric control |

| Main forming unit driving motor power | 7.5kW |

| Curving motor power | 3+1.1+1.1kW |

| Electric cutting motor power | 3kW |

| Material of rollers | 45# steel, quenched HRC 58-62 |

| Material of roller shafts | 45# steel, adjusted |

| Material of cutting blade | Cr12Mov, quenched |

| Stations of rollers | 13 steps |

| Forming speed | 10000~12000 mm/min |

| Max span: | 36000mm |

Typical buildings:

MIC-120 K Span Roll Forming Machine

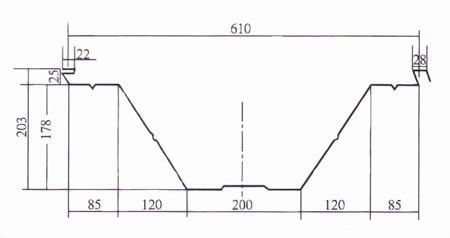

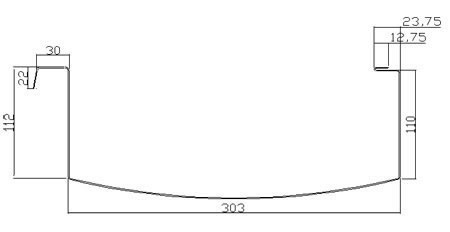

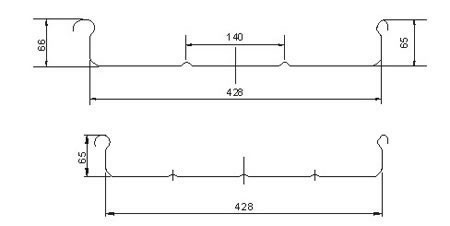

Profile:

Features of MIC-240 Super K Span Roll Forming Machine:

1 Rollers are made of good steel, coated with rigid chrome.

2 The rubber feeding device of it can feed 0.5-1.5mm color steel sheets.

3 Light and convenient hoist, only 2kg (those from USA are 30kg). So quick and convenient installation is possible.

4 Large span, high corrugation, high tension strength, without nuts.

5. During production, it is unnecessary for you to adjust the clearance between top and bottom rollers.

Applications of MIC-240 Super K Span Roll Forming Machine

This roll forming machine is widely used in the construction of factories, garages, hangars, stadiums, exhibition halls, theaters, and so on.

Main Technical Data of MIC-120 K Span Roll Forming Machine:

| Mounting dimension | 8900mm x 2250mm x 2400mm |

| Total weight | about 9500kg |

| Control system | electric control |

| Main forming unit driving motor power | 7.5kW |

| Curving motor power | 3+1.1+1.1 kW |

| Electric cutting motor power | 3kW |

| Material of rollers | 45# steel, quenched HRC 58-62 |

| Material of roller shafts | 45# steel, adjusted |

| Material of cutting blade | Cr12Mov |

| Step of rollers | 13 steps |

| Forming speed | 10000~12000 mm/min |

| Max span | 24000mm |

Standing Seam (Bemo) Roll Forming Machine

Zhenhuan is a forming machine manufacturer and supplier in China. You can find high quality roll forming machine, spiral duct forming machine, plasma cutting machine, welding machine and other forming machines in our company.

English

English Español

Español Русский

Русский Português

Português Français

Français