Air Conditioner Radiator Core Making Machines

This product has been discontinued and removed from our shelves.

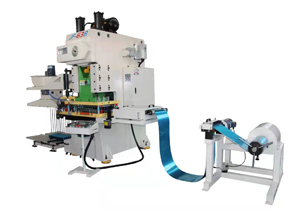

Air Conditioner Aluminum Fin Punching Press Line

The automatic fin press line includes an auto decoiler, a lubricant oil spreading device, high speed punch press, and a fin unloading and stacking device. It can work on both aluminum and copper fin plates:

The line is PLC controlled, HMI operated, and fully automatic. We supply both double crank and single crank high speed punch presses.

JG36 Series Double-Crank Punch Press

| Item | JG36-63 | JG36-80 | JG36-100 |

| Nominal force (kN) | 630 | 800 | 1000 |

| Ram stroke (mm) | 40 | ||

| Upper mold adjustment (mm) | 80 | ||

| Die height (mm) | 275 | ||

| Die height adjustment (mm) | 20 | ||

| Number of strokes (times/min) | 120-300 | ||

| Worktable dimension (mm) | 1150 x 1500 | 1380 x 1500 | 1550 x 1500 |

| Suitable band width (mm) | 700 | 860 | 1120 |

| Suitable coil OD. (mm) | 1200 | ||

| Main driving motor power (kW) | 8.5 | 11 | 13 |

JG31 Series Single-Crank Punch Press

| Item | JG31-45 | JG31-63 |

| Nominal force (kN) | 450 | 630 |

| Ram stroke (mm) | 40 | 45 |

| Upper mold adjustment (mm) | 70 | 80 |

| Die height (mm) | 275 | 275 |

| Die height adjustment (mm) | 40 | 40 |

| Number of strokes (times/min) | 120-300 | 120-300 |

| Worktable dimension (mm) | 820 x 1400 | 1050 x 1550 |

| Suitable band width (mm) | 350 | 500 |

| Suitable coil OD. (mm) | 1000 | 1000 |

| Main driving motor power (kW) | 5.5 | 7.5 |

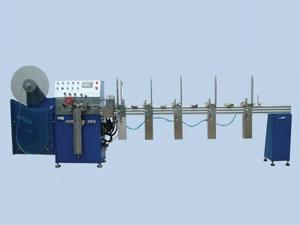

Automatic Copper Tube Long U Bending Machine

This machine is specially designed for straightening and cutting copper tubes and bending them into long U copper tubes used in air conditioner radiator cores.

The machine is PLC controlled with HMI operation and fully automatic.

Technical Data

| No. | Item | Data |

| 1 | Suitable copper tube material | TP2 (M) |

| 2 | Suitable copper tube size | Φ9.52 / Φ7 |

| 3 | Suitable length of long U tube | 190mm~ 2500mm (or customized) |

| 4 | Number of tubes to bend in one time | 6 (or customized) |

| 5 | Bending speed | Not more than 11 seconds per cycle (@L=1000mm) |

| 6 | Bending radius error | ±0.05mm |

| 7 | Bend height error | ±0.5mm |

| 8 | Length error | ±0.5mm @ L = 200-1300mm ±0.8mm @ L = 1300-2500mm |

| 9 | Two ends length difference | Less than 1.0mm |

| 10 | Wall thickness reduction ratio | Less than 30% |

| 11 | Section deformation ratio | Less than 15% |

| 12 | Straightness error | Less than 3mm (every 1000mm long) |

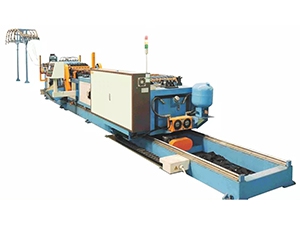

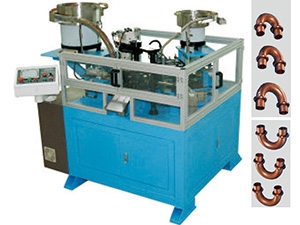

Automatic Copper Tube Small U Bending Machine

This machine will automatically feed, bend, cut and release small U copper tubes.

Technical Data

| No. | Item | Data |

| 1 | Suitable copper tube material | TP2 (M) |

| 2 | Suitable copper tube size | Φ9.52 x 0.6mm / Φ7 x 0.5mm |

| 3 | Suitable small U size | Φ9.52 x 25mm / Φ7 x 21mm |

| 4 | Number of tubes to bend in one time | 3 (or customized) |

| 5 | Bending speed | 7~12 seconds per cycle |

| 6 | Bending radius error | ±0.05mm |

| 7 | Bend height error | ±0.5mm |

| 8 | Two ends length difference | Less than 0.5mm |

| 9 | Wall thickness reduction ratio | Less than 30% |

| 10 | Section deformation ratio | Less than 15% |

| 11 | End mouth roundness | Less than 5% |

| 12 | Burr height | Less than 0.2mm |

Copper Tube Welding Ring Assembling Machine

This machine utilizes magnetic vibrating feeding, servo rotation, PLC control and HMI operation.

Technical Data

| No. | Item | Data |

| 1 | Suitable copper tube OD | Φ7, Φ7.94, Φ9.52mm |

| 2 | Suitable copper tube wall thickness | 0.3-0.5mm |

| 3 | U bend center distance | 16-22mm @Φ7, Φ7.94 22-26mm @Φ9.52 |

| 4 | Center distance error | ±0.15mm |

| 5 | Working speed | 1-3 seconds per cycle |

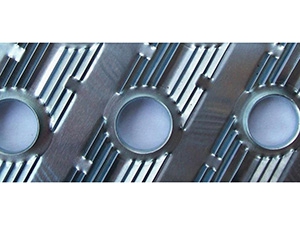

Radiator Core Copper Tube Expanding Machine

In order to carry out copper tube expansion, we have both vertical and horizontal expanders. Detailed configurations are based on the copper tube size, rows, quantity per row, core length and more.

Horizontal Expanding Machine

Vertical Expanding Machine

English

English Español

Español Русский

Русский Português

Português Français

Français