- Home

- Products

- Welding Machine

- Spiral Fin Tube Welding Machine

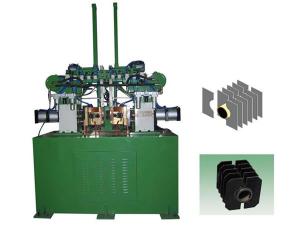

Spiral Fin Tube Welding Machine

The spiral fin tube welding machine is employed to weld the steel spiral fin to the steel tube. The spiral fin tube manufactured is widely used in industrial and home heat exchanging project.

Features

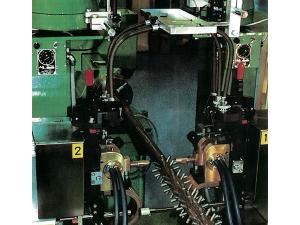

1. The high frequency spiral fin tube welding machine adopts PLC for double frequency conversion linkage control on the product.

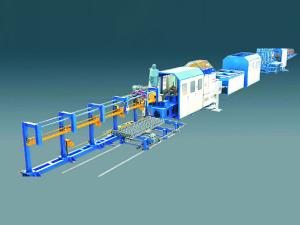

2. The material loading, clamping, feeding, welding, and material unloading can be completed automatically.

3. In addition to the Panasonic DVP controller, the spiral fin tube welding machine also employs Panasonic HMI for convenient operation.

4. Constructed with 40Cr guide rail, the spiral fin tube welder is characterized by excellent welding performance and long lifespan.

Main Parameters of Spiral Fin Tube Welding Machine

| Item | CPG-9I | CPG-10 | |||

| Max. fin tube length | 8m/12m/16m | 12m/16m | |||

| Applicable base tube diameter | Φ20mm-Φ159mm | Φ20mm-Φ219mm | |||

| Fin spiral pitch | 4-30mm | 4-50mm | |||

| Fin material | Carbon steel, steel alloy, stainless steel | ||||

| Fin material thickness | 0.8-3mm | 0.8-3.5mm | |||

| Fin material width | 10-30mm | 10-40mm | |||

| Spiral fin material feeding speed | 30m/min | ||||

| Spiral pitch tolerance | ±0.1mm | ||||

| Mandrel rotating speed | 0-350rpm | ||||

| length of base tube terminal without spiral fin | Less than 20mm | ||||

| HF power | Capacity | 100kVA | 200kVA | 300kVA | 400kVA |

| Applicable tube diameter | < 60mm | < 114mm | < 159mm | < 219mm | |

Photos of Welding Equipment & Finished Spiral Fin Tubes

English

English Español

Español Русский

Русский Português

Português Français

Français