- Home

- Products

- Welding Machine

- Wheel Rim Bending Machine

We can provide all the related machines for producing wheel rims, such as rim bending machine, rim butt welding machine, rim trimming machine, rim rolling machine, and so on.

Wheel Rim Bending Machine

Description of Wheel Rim Bending Machine

This wheel rim bending machine is used to bend steel plate into round shape as the semi-product for the production of wheel rim. The bending rollers can be adjusted for processing work piece in different diameters.

Main Technical Parameters of Wheel Rim Bending Machine

| Item | Specification |

| Wheel rim wall thickness | 2-6mm |

| Wheel rim width | 4-8" |

| Suitable rim diameter | 12-18" |

| Applicable material | Carbon steel |

| Spindle speed | 55rpm |

| Main drive motor power | 7.5kW |

| Spindle drive mode | Universal joint |

| Finished product ejection | Pneumatic |

| Material of rollers | 45# steel processed with hardening & tempering technology |

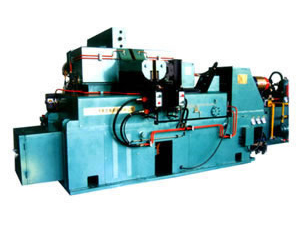

Wheel Rim Butt Welding Machine

Description of Wheel Rim Butt Welding Machine

Stable and reliable, the wheel rim butt welding machine adopts hydraulic drive system. Flash welding and upset welding technology are applied for heating and welding work piece, respectively.

Technical Parameters of Wheel Rim Butt Welding Machine

| Item | Specifications |

| Rated transformer capacity | 800kVA |

| Rated primary voltage | 380V |

| Suitable wheel rim section area | 400-4500mm2 |

| Max. rim width | 500mm |

| Min. rim width | 100mm |

| Welding speed | 0.8-30mm/min |

| Max. clamping force | 600KN |

| Max. upsetting force | 300KN |

| Max. adjustable range of jaw | 80mm |

| Adjustable voltage range | 7.6-14.6V |

| Hydraulic working pressure | 5-15MPa |

| Hydraulic pump motor power | 22kW |

| Cooling water pressure | 0.2MPa |

| Cooling water flow | ≥3000L/N |

| Duty cycle | 60% |

| Machine dimension | 2800×2000×2500mm |

| Machine weight | 15 tons |

Wheel Rim Trimming Machine

Description of Wheel Rim Trimming Machine

The wheel rim trimming machine is composed of skiving & planning machine, roll flattening machine, and end cutting machine. The material loading and unloading are carried out manually.

Technical Parameters of Wheel Rim Trimming Machine

| Item | Specification |

| PLC | Omron from Japan |

| Touch screen | Delta from Taiwan |

| Button | Schneider |

| Electric control cabinet | Electric box |

| Sensor | Imported from Japan |

| Lubrication pump | BIJUR dry sump oil pump from USA |

| Hydraulic station motor power | 45kW |

Wheel Rim Rolling Machine

Description of Wheel Rim Rolling Machine

Specially offered for final processing of wheel rims, the wheel rim rolling machine is applicable for processing material in different shapes because of the changeable moulds. Driven by hydraulic system, this product is quite stable and reliable for use.

Technical Parameters of Wheel Rim Rolling Machine

| Item | Specifications |

| Applicable wheel rim diameter | 12-18' |

| Suitable wheel rim width | 4-8' |

| Main shaft diameter | 135mm |

| Main shaft length | 350mm |

| Main forming roll quantity | 2 |

| Guide roller quantity | 2 |

| Side guide shaft diameter | 90 mm |

| Side guide stroke | 200mm |

| Main shaft speed | 50-450rpm |

| Max. distance between upper & lower main shaft | 362mm |

| Min. distance between upper & lower main shaft | 262mm |

| Adjustable tilt angle of main shaft | 0-1.5° |

| Adjustable distance of lower main shaft axial | ± 2mm |

| Lower main shaft rising force | 10000kgf |

| Main shaft torque | 3850N·m |

| Hydraulic pump motor power | 68kW |

| Lubricating mode | Compulsive centralized lubrication |

| Machine dimension | 2000×1600×1800mm |

Besides Wheel Rim Butt Welding Machine, Zhenhuan also supplies roll forming machine, spiral duct forming machine, plasma cutting machine etc.

If you have a need for our welding machines, please contact us immediately.

English

English Español

Español Русский

Русский Português

Português Français

Français