- Home

- Products

- Welding Machine

- 3D Truss Girder Welding Machine

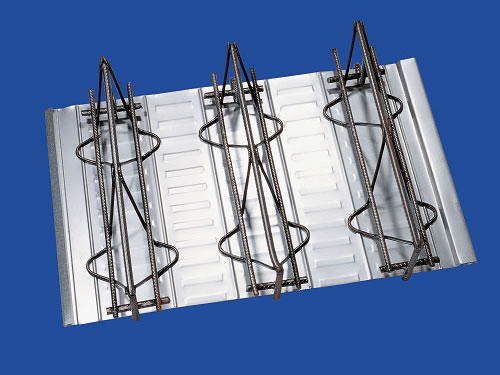

3D Truss Girder Welding Machine

The 3D truss girder welding machine utilizes three coiled steel ribbed bars and two coiled round steel bars as the raw material for production.

Features of 3D Truss Girder

1. The 3D truss girder is a kind of advanced invention for building construction.

2. It can be used together with steel floor panel for direct pouring, reducing time for on-site rebar binding. Therefore, the working efficiency is improved and the construction period is shortened, accordingly.

3. With reliable structural stress, the 3D truss girder requires little support during construction, and the rigidity of the floor panel is improved, as well.

Technical Parameters of 3D Truss Girder Welding Machine

| Item | Unit | Specifications |

| Load bearing capacity of feeding unit | kg | 1500 |

| Quantity of feeding unit | pc | 5 |

| Rebar straightening speed | m/min | 30 |

| Rebar feeding motor power | kW | 3.7×5 |

| Straightening motor power | kW | 7.5×3 |

| Truss rebar forming motor power | kW | 7.5 |

| Welding transformer power | KVA | 125×2 |

| Hydraulic station motor power (for cutting) | kW | 15 |

| Hydraulic pressure | MPa | 25 |

| Rebar bending motor power | kW | 7.5 |

| Stacking chain moving motor power | kW | 3 |

| Stacking rack elevating motor power | kW | 3 |

| Truss rebar bending pitch | mm | 200 |

| Truss girder height | mm | 70-300 |

| Truss girder width | mm | 60-90 |

| Longitudinal rebar diameter | mm | 5-12 |

| Truss rebar diameter | mm | 4-7 |

| Truss girder length | m | 2.4-12 |

| Production speed | m/min | 0-18 |

| Air pressure | MPa | 0.6 |

| Air consumption | m3/min | 1.8 |

Inquiry Form

English

English Español

Español Русский

Русский Português

Português Français

Français