- Home

- Products

- Air Conditioner & Refrigerator Making Machines

- Drier Filter Tube Spinning Machine

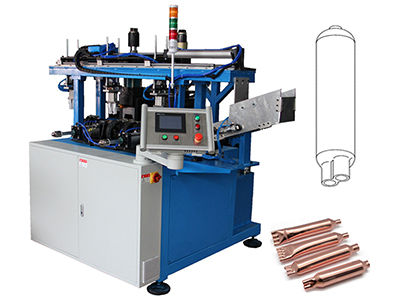

Drier Filter Tube Spinning Machine

Description

The tube spinning machine is specially designed for closing or necking-in metal tubes for oil storage, muffler and filter drier for air condition, refrigerator, heater, automotive, etc.

Main Features

1. Two axis CNC control, small error, high speed

2. Hydraulic system is equipped

with water cooling system

3. High speed mandrel speed 2800rpm, inverter control,

speed adjustable

4. Automatic loading, unloading Main Technical Data of Tube Spinning Machine

Main Features of Tube Spinning Machine

| No. | Item | Data |

| 1 | Max. tube diameter and wall thickness | Φ30×1mm (or 50×1mm, 80×1mm) (copper) |

| 2 | Min. tube diameter and wall thickness | Φ8X1mm (copper) |

| 3 | Max. workpiece length | 200MM |

| 4 | Min. workpiece length | 40MM |

| 5 | Average working efficiency | 15s per piece |

| 6 | Control method | CNC double-axis control |

| 7 | Loading/unloading method | automatic |

| 8 | Driving method | Hydraulic + pneumatic |

| 9 | Main spindle motor | Inverter control speed adjustable |

| 10 | Total power consumption | 6.5KW |

| 11 | Electric power | 380V 50HZ |

| 12 | Air source | 0.5-0.8MPa |

| 13 | Hydraulic pressure | 0.5-6MPa |

As a professional tube spinning machine supplier in China, we can provide any kind of metal spinning machines for any special purposes!

We can provide complete machines for air conditioner and refrigerator drier filter production:

Drier Filter Copper Mesh Filling Machine

This drier filter copper mesh filling machine is specially designed for inserting copper mesh and screen and filling drying agent (molecular sieve) in a certain volume to spun drier filter tubes. All actions are fully automatic.

| Item | Data |

| Suitable copper tube diameter | φ16~25mm |

| Suitable copper tube length | 70~165mm |

| Filling molecular sieve weight range | 6~20g |

| Molecular sieve filling adjusting range | 2~4g (without changing counting cup) |

| Working productivity | 4~5 seconds per piece |

| Distance between outlet and mesh (L1) | 0~83mm |

| Distance between inlet and mesh (L2) | 33~133mm |

| Re-positioning precision of mesh inserting | ±0.3mm |

| Re-positioning precision of rotating spindle | ±0.2º |

Filter Tube Two-way Forming Machine

This two-way forming machine is specially designed for forming one end of copper drier filters to be two-way, three-way, or four-way inlet, for connecting capillary tubes.

It is a hydraulic tube end forming machine with automatic loading and unloading function, and servo motor driving manipulators.

Copper tube feeding is achieved by hopper, and manual loading.

This machine is PLC control, HMI operation, fully automatic.

| Item | Data |

| Suitable copper tube diameter | φ16~30mm |

| Suitable copper tube length | 50~165mm |

| Working productivity | 20~30 pcs/min |

| Tube mouth deformation ratio | < 3% |

| Hydraulic station motor power | 3kW |

English

English Español

Español Русский

Русский Português

Português Français

Français