- Home

- Products

- Air Conditioner & Refrigerator Making Machines

- Copper Tube Straightening Flaring & Bending Machine

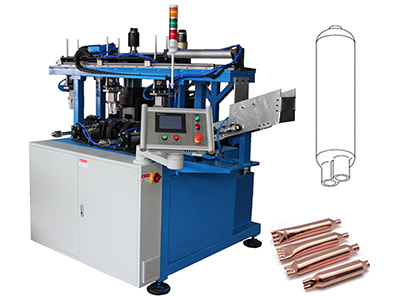

Copper Tube Straightening Flaring & Bending Machine

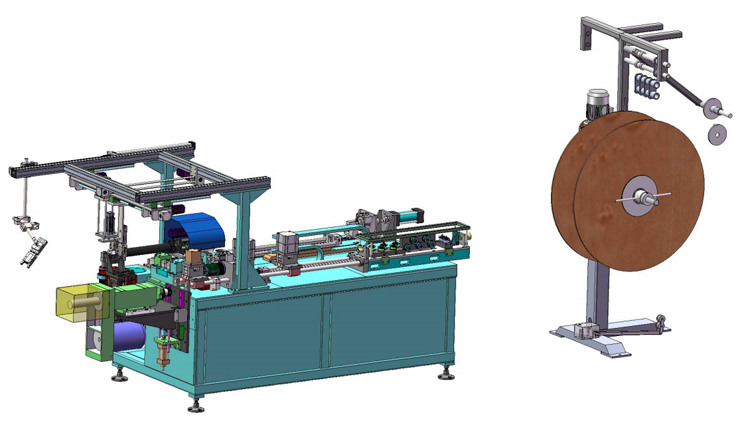

Description of Copper Tube Straightening Flaring & Bending MachineThis copper tube straightening flaring & bending machine is specially designed for decoiling, straightening, end forming, bending, and cutting coil copper tubes into different shapes, used in air conditioners and heat exchangers.

This machine is an integrated machine, combing straightening, end forming and 3D bending together. There is robot manipulator automatically move end-formed parts to bending station.

The machine is PLC control, HMI operation, full automatic, high uniformity, no labor required.

This machine line is designed to be heavy-duty for max. copper tube OD 22mm. The clamping force for bending will be hydraulic and servo motor for bending will be much bigger.

Main Technical Data of Copper Tube Straightening Flaring & Bending Machine| Item | Data | ||

| Suitable copper/aluminum tube material | Hard / soft | ||

| Suitable copper tube reel size | Max. weight 280kg Max. OD: Ф1250mm; ID: Ф130mm | ||

| Suitable copper tube diameter | Max. Φ22mm x 1.2mm | ||

| Bending station | Bending radius | Max. R 60mm; Min. R 10mm | |

| Max. Workpiece length | 1200mm | ||

| Feeding axis (X) | Stroke | 0 - 1200mm | |

| Speed | 0 - 1200mm/sec | ||

| Precision | ±0.05mm | ||

| Rotating axis (Y) | Angle | 0 - ±360° | |

| Speed | 0 - 600°/sec | ||

| Precision | ±0.05° | ||

| Bending axis (Z) | Angle | 0 - 200° | |

| Speed | 0 - 300°/sec | ||

| Precision | ±0.05° | ||

| Decoiling & straightening station | One-time feeding stroke | Max. 1000mm | |

| Linear straightness error | ≤2‰ | ||

| Re-positioning error | When L≤1000mm, ≤0.3mm When L≥1000 mm, ≤0.6mm | ||

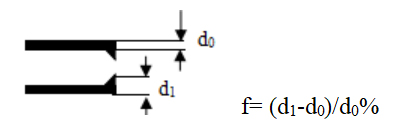

| Tube end ID reduction ratio | f < 20% * | ||

| Length difference between tubes | ≤0.5mm (L=1000) | ||

| Surface condition after cut | No apparent scratch, drawing marks; no burrs | ||

| Roundness of cut tubes | When diameter ≤ ф12.7, ≤3% When diameter >ф12.7, ≤0.4mm | ||

| End forming station | Power | Hydraulic | |

| Working-stations | 1 | ||

| End forming method | flaring | ||

| Overall equipment effectiveness | 3~4 seconds per bend | ||

| Electric power | 380V / 50Hz / 7.0kW | ||

| Whole line dimension | L4000 x W1000 x H1300mm | ||

| Whole weight | 1000kg | ||

| Pneumatic source | 0.5 - 0.7MPa | ||

| Hydraulic pressure | 5 - 7MPa | ||

* 1-When cutting length is less than 100mm, there will be pre-stretching function.

* 2- Tube end ID reduction ratio means:

English

English Español

Español Русский

Русский Português

Português Français

Français