- Home

- Products

- Wire Bending Machines

- Hangar Hook Bending Machine

Hangar Hook Bending Machine

Description of Hanger Hook Bending Machine

This hangar hook bending machine combines the functions of hook forming and hook end threading together. Generally one end is threaded, and the other end has two shapes (one shape is bended, the other is cold headed). Different shape and different heading treatment can be achieved by changing moulds.

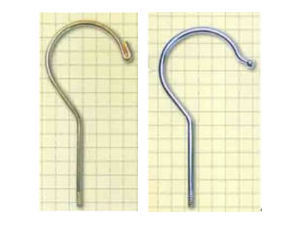

When the hook likes below picture, then there need a separate press plus heading tool to form the heading end. This process is done separately after hook is bent:

Technical Parameters of Hanger Hook Bending Machine

| Item | HHBM30 | HHBM43 |

| Applicable material | Galvanized steel wire, carbon steel wire | |

| Wire diameter | 1.5-3.0mm | 2-5mm |

| Max. wire length | 160mm | 160mm |

| Production speed | 40-50pcs/min | 25-30pcs/min |

| Main motor power | 1.5kW | 2.2kW |

| Dimension | 1360×1070×1980mm | |

| Weight | About 400kg | |

Technical Parameters of Threading Machine

| Item | HFR30 | HFR43 |

| Applicable material | Galvanized steel wire, carbon steel wire | |

| Wire diameter | 2-3.0mm | 2-4.3mm |

| Production speed | 25-30pcs/min | 25-30pcs/min |

| Main motor power | 2.2kW | 2.2kW |

| Dimension | 1480×1000×680mm | |

| Weight | About 200kg | |

Inquiry Form

English

English Español

Español Русский

Русский Português

Português Français

Français