- Home

- Products

- Transformer Making Machine

- Copper Aluminum Continuous Extrusion Machines

Copper Aluminum Continuous Extrusion Machine

Working Principles of Copper Strip Continuous Extrusion Line

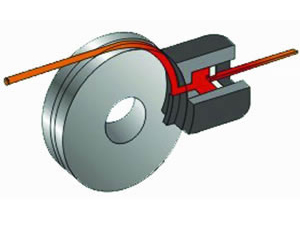

The MFCCE series copper Strips Continuous Extrusion Line makes use of the advanced technology in the world. Such blank material as copper or aluminum rods will be continuously fed into a revolving squeezing wheel with a fixed groove. At this time, due to the enormous frictional force and extrusion force, a sufficient temperature can be achieved. This temperature makes the materials to re-crystallize. Then, the material will be extruded and shaped out from the special dies. Thus, various kinds of aluminum or copper profiles will be manufactured continuously.

Applications of Copper Strip Continuous Extrusion Line

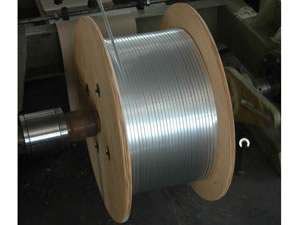

This MFCCE series copper Strips Continuous Extrusion Line is capable of manufacturing various copper bar, copper busbar, copper rod, copper flat wire, aluminum flat wire, aluminum round pipe, as well as aluminum flat pipe with holes, etc.

Advantages and Features of Copper Strip Continuous Extrusion Line

1. The finished products come with a smooth and bright surface without burr. The feature of high-precision physical dimension is offered as well.

2. The end products also have these features including fine tissue, refined crystal grain structure, good performance evenness, as well as perfect electrical conductivity.

3. Their surface is close to the status of perfect soft and semi-hard however long they are.

4. Our copper Strips Continuous Extrusion Line is compact and energy-saving, without wasting any materials during the manufacturing process.

Technical Specifications of Copper Strip Continuous Extrusion Line

| Item | MFCC300 | MFCC350 | MFCC400 | MFCC550 | MFCC630 | ||

| Copper | Aluminum | ||||||

| Diameter of squeezing wheel (mm) | 300 | 350 | 400 | 550 | 630 | ||

| Material | Copper,copper alloy | AluminumLD31,Lf21 alloy | Copper or copper alloy | ||||

| Diameter of blank material (mm) | Φ8-12.5 | Φ9.5-12 | Φ12.5-Φ16 | Φ20 | Φ30 | Φ30 | |

| Maximum product width (mm) | 40 | bar 80rod Φ 40 | Bar 70rod Φ 80 | bar 260 rod Φ 90 | bar 320rod Φ 100 | ||

| Product section area (mm2) | 5-150 | 6-30(round); ≤50 (flat) | 10-800 | 100-2400 | 300-5000 | 400-7000 | |

| Average productivity (kg/h) | 400 | 180 | 780 | 1200 | 2000 | 2500 | |

Product Samples

English

English Español

Español Русский

Русский Português

Português Français

Français