- Home

- Products

- Transformer Making Machine

- Paper Taping Machine

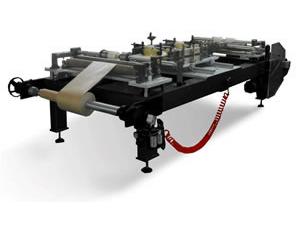

Paper Taping Machine

The configuration of the paper taping machine is on the basis of taping layers, quantity of wires required, and wire reel sizes. This device is able to perform single-wire taping or multi-wire taping. The taping layer ranges from 2 to 60 layers.

Machine Compositions

1. Pay-off stands

2. Main machine

3. Take-up stands

4. Control system

Technical Parameters

1. Wire Specification

Material: copper or aluminum flat wire

Width: 5~20mm

Thickness: 1~16mm

Section area: 10~200mm2

Width/thickness ratio: 0.4~12

2. Paper Specification

Thickness: 0.040~0.125mm

Width: 10~30mm

3. Taping Head Specification

Taping pitch: 8~30mm (stepless adjustable)

Taping pitch tolerance: ±0.4mm

Taping tension: mechanically automatic adjusting, constant tension

Rated rotating speed: 800rpm

Working speed: 600rpm

Paper disc diameter: outer diameter: 330mm, inner diameter: 75mm

Quantity of paper disc on each taping head: 3 or 4 pcs

Paper break sensor: This sensor is used to detect whether paper tape is interrupted or not. If the phototube detects the breaks, our paper taping machine will automatic stop.

4. Caterpillar towing device:

The thicker synchronized gear type belt allows this machine to ensure a stable and reliable liner speed.

5. A fully enclosing cover contributes to prevention of the dust.

6. Take-up device: moment motor drive, constant-tension taking-up, slick rod wiring, take-up disc motorized elevating.

Fiberglass & Film Taping Machine

This kind of taping machine is specially designed for applying fiberglass and film to copper or aluminum wires with section areas of 5-40 mm2. The equipment adopts a dual-headed structure and each of the heads has its own control system. In addition, if our tapping machine is applied with high-frequency sintering device, it is able to manufacture special film-taped magnet wires.

Machine Compositions

1. Pay-off stand

2. Wire straightening device

3. Wire polishing & cleaning device

4. Film taping head

5. Fiberglass taping head

6. Varnishing device

7. Towing device

8. Baking oven

9. Take-up stand

Technical Data

| Item | Data |

| Suitable wire section area | 5~40mm2 |

| Fiberglass yarn | inner diameter 42mm |

| yarn length 75mm | |

| spool length 95mm | |

| Production speed | 2.5~4m/min |

| Film taping pitch | 6~24mm |

| Fiberglass taping pitch | 2~10mm |

| Baking oven | 2000mm x 8 pieces |

| Towing wheel diameter | 800mm |

| Main driving motor power | 3kW x 2 |

| Total electricity consumption | about 60kW |

| Floor areas | about 25m x 3.5m |

English

English Español

Español Русский

Русский Português

Português Français

Français