- Home

- Products

- Transformer Making Machine

- APG Epoxy Resin Casting Machine

APG Epoxy Resin Casting Machine

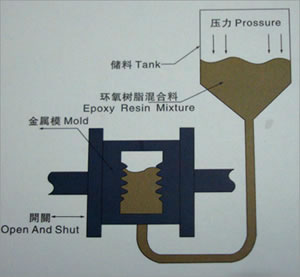

Our WHAG-888 APG Epoxy Resin Casting Machine adopts the automatic pressure gelation processing technology. It is used to cast high voltage electrical components with epoxy resin. The APG technology can reduce the casting duration from dozen hours (by conventional vacuum casting method) to dozen minutes. Also, the technology can control exothermic effect well and is good for compensating shrinkage caused by curing reaction, thereby ensuring that the cast products offers good dimensional stability and high mechanical strength.

The APG casting equipment is especially ideal for casting instrument transformers, pole rod of vacuum breaker, cover of SF6 breaker, as well as other electrical products featuring thin-wall, complicated, or multiple sides core pulling, etc.

The APG technological process includes three stages which are pre-mixing, automatic pressure gelating, as well as curing. Our APG Epoxy Resin Casting Machine needs to be applied with various components including moulds, pre-mixing device, movable injection pressure vessel, hydraulic pressure gelating machine, air compressor, curing oven, and so on.

Our APG Epoxy Resin Casting Machine comes with a double station, and mould plates are fixed in the middle of the frame. While one station working, the other station will stop to take out the finished products. Therefore, the production efficiency is significantly improved.

| Items | Data |

| APG Epoxy Resin Casting Machine | |

| Die assembly plate dimension (heating plates) | 800 x 800mm |

| Die clamping force | 200kN |

| Die clamping speed | 3.2m/min |

| Die opening speed | 5m/min |

| Die clamping distance (distance between heating plates) | 200-1200mm |

| Min. distance between upper core pulling and die plate center | 150mm |

| Min. distance between lower core pulling and die plate center | 150mm |

| Upper and lower die assembly plate dimension | 520x240mm |

| Hydraulic station motor power | 7.5kW |

| Hydraulic pressure | 30MPa |

| Total heating power | 30kW |

| Body tilting degree | 0-7° |

| Outline dimension (L x W x H) | 6630x1350x3195mm |

| Weight | about 4000kg |

| Pre-mixing device & movable vessel | |

| Outline dimension | 1830 x 850 x 2500mm |

| Mixing motor power | 3kW |

| Mixing head elevating (hydraulic driven) motor power | 0.75kW |

| Vacuum pump speed | 8L/S |

| Vacuum degree | 0.5mbar |

| Vacuum pump motor power | 1.5kW |

| Capacity of mobile pressure vessel | 100L |

| Heating method of pressure vessel | Oil heating |

| Heating power | 1.5kW |

English

English Español

Español Русский

Русский Português

Português Français

Français